Electric Tube Rolling Systems

Electric tube rolling systems consist of a solid-state torque controller. Whereas the actual driving motor has the same basic design as the PTR-02 and PTR-03.

Features:

- Heavy duty German made Eibenstock motors form the heart of these drivers.

- Continuous duty cycle operations.

- High torque to weight ratio machines.

- Available in 120/240 Volts 50/60Hz.

Follow the link below for a full breakdown of controls for the TCW Torque Controller.

Electric tube Rolling Systems with Torque Control

The four sizes of drivers work with the same torque controller. The TCW Controller recognizes the driver when connected to the controller. Each of the four drivers has specific torque ranges. The four drivers can cover from 1/4″ OD to 4.0″ OD.

When rolling many tubes of the same size and characteristics. The controller can be set to torque values when reached. The driver pauses and reverses out of the tube. Then pauses again to allow the operator to place the expander in the next tube. All these values are adjustable to permit continuous operation.

Rolling Drive Selection

MPB-0

The MPB-0 Is for small tubes in oil coolers and radiator-type heat exchangers.

Steel Tubes from 1/4″OD to 3/8″ OD.

MPB-1

The MPB-1 Is for tubes in oil coolers and heat exchangers.

Steel Tubes from 1/4″OD to 5/8″ OD.

MPG-2

The MPG-2 Is for tubes heat exchangers and small tube boilers.

Steel Tubes from 5/8″OD to 1.3/4″ OD.

MPG-3

The MPG-3 Is for tubes in air heaters and boilers.

Steel Tubes from 1.0″OD to 3.0″ OD.

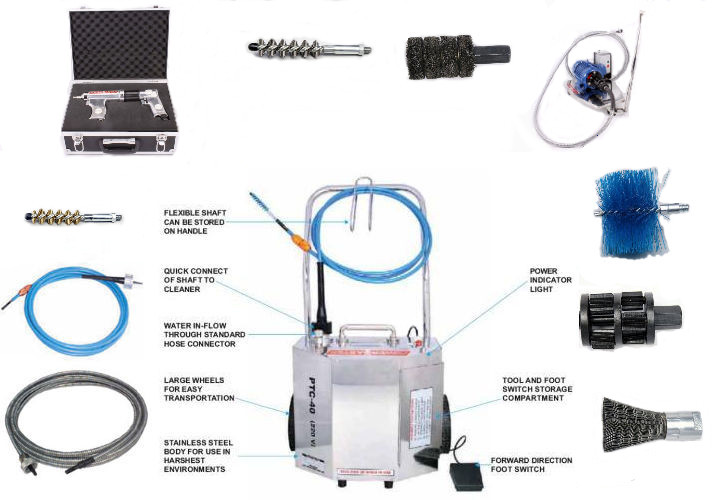

Accessories for Tube Rolling Systems

- Collapsible Trolley.

- TCW Torque Controller.

- Spring Balancer to take the weight of the telescopic shaft and expanders.

- Swivel Bracket to hold the tube rolling motor.

- Telescopic Shaft

These are custom-made rolling systems built here in Canada. With minimum effort, the operator can move from one tube to another.

The overhead arm supports the spring balancer which balances the weight of the telescopic shaft and expander.

The purpose of the telescopic shaft is to free the operator from handling drives. These have an extension length of approximately 500mm. The design is sturdy, absorbing all inherent torque from the tube rolling motor. With just one hand on the handle on the shaft, the operator can move from one tube to another.

Control of the tube rolling machine drive is by the foot pedals which control forward. reverse and fully auto.

Voltage stabilizers and transformers can be incorporated within the design of the system.

Why Choose Powermaster of Canada

Versatile

Our Electric Tube Rolling Systems are versatile and can be used for various heat transfer and construction needs.

Precise

Our systems provide precise control over the torque applied, resulting in consistent tube expansion and high-quality results.

Efficient

Our systems are designed for maximum operator efficiency, with foot pedals allowing for easy control of the rolling drives.

Reliable

Our Electric Tube Rolling Systems are heavy-duty, German-made, and have a continuous duty cycle operation.

Rolling the Hot Pass

This is the hot pass where the flame comes out of the Morrison Tube and is turned around on the door. The tubes are straight rolled and then welded to the tube sheet. This has nothing to do with sealing the tube. This is to transfer the heat around 2000 degrees F. into the tube sheet from the tube ends. If this is not done, tube ends could heat and crack, leading to total failure.

Once welding is complete, the proper procedure is to re-roll the joint to illuminate any movement in the rolled joint caused by the welding of the tube.

In summary, the attainment of high-quality joints in boiler tube welding hinges on adhering to best practices throughout the process. Essential steps include proper preparation, such as cleaning and fit-up, to ensure a clean, well-aligned joint. The selection of a suitable welding technique and adherence to recommended welding parameters are critical for achieving the desired weld quality. A stable arc, controlled heat input, and the application of post-welding inspection techniques are vital for detecting and correcting any defects. Following these best practices enables manufacturers and maintenance staff to produce superior joints in boiler tube welding, thereby enhancing the performance and safety of boilers.