Powermaster Industrial Supplies Tel: (613) 764-0572

- Home

- Tube Tools

Condenser Expanders

Tube Installation Tools

Boiler Expanders

Tube Removal Tools

Internal Tube Cutters

Pipe Bevellers/Weld Removal

Hydrostatic Test Pumps

Rolling Systems

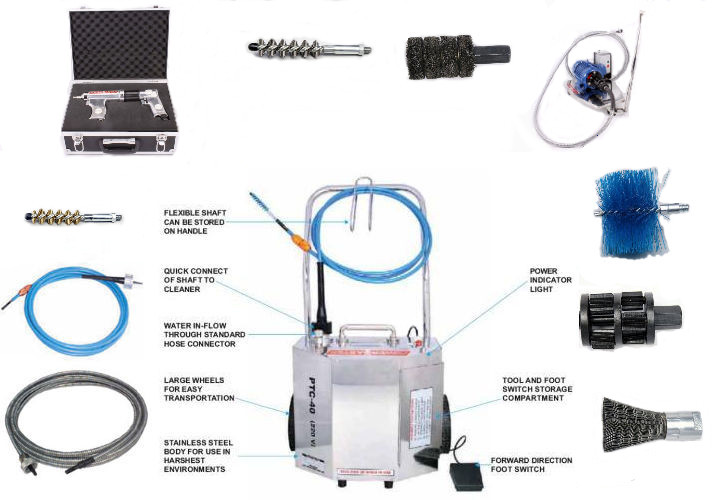

Cleaning Tools and Equipment

- Pipe Bevelling

Pipe Bevellers

Electric and Pneumatic

- Tube Cleaning

- Metal Working Tools

- Contact