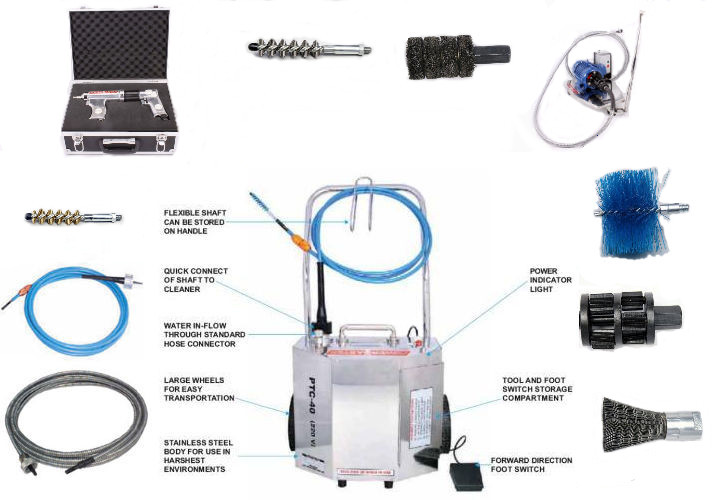

1200-5 Series Tube Expanders

Uses:

The 1200-5 Series tube expanders are used on heat exchangers with thin-walled tubes and thick tube sheets. A 5-roll system avoids the chances of triangulation like between 3 rolls and thin walls. Especially when using exotic tube material like Hasteloy, duplex stainless and other exotic alloys. Tube sheet range from 1/2″-12.3/4″.

Advantages of the 1200-5 Tube Expanders:

One of the most popular tube expanders when working with thin-walled tubes is the 1200-5 series tube expanders. These expanders give a more concentric finish and when using exotics. Memory in the original form has less chance of returning to its original shape.

Tube and Sheet Sizes:

- 3/4″-1.1/2″” OD.

- Tube Sheet Adjustable Range 1/2″-12.3/4″.

- 3/8″ and 1/2″ Square mandrel drive.

Follow the link below for the full PDF specifications:

Heat exchangers are crucial components in many industrial processes. Especially utilized to transfer heat from one medium to another. without the two mediums coming into direct contact with each other. This allows for the efficient exchange of heat in a controlled manner. Therefore exists for maintaining optimal operating conditions in various industrial applications.

Heat exchangers when used in many industries. These include, chemical processing, petroleum refining, power generation, HVAC systems and food processing. Found in equipment such as boilers, chillers, condensers, evaporators, and heat pumps.

The main role of heat exchangers in industry is to facilitate the transfer of heat. Whereas between two fluids or gases. Therefore transferring heat from a hot fluid to a cooler one. Thus maintain a specific temperature within a system. This process helps to improve energy efficiency and reduce operating costs. At the same time, enhancing overall system performance.

There are several types of heat exchangers used in industry. These including shell and tube heat exchangers by far the most common. Plate heat exchangers, air-cooled heat exchangers, and finned tube heat exchangers. Each type has its own unique design and operating characteristics. Therefore that makes them suitable for different applications.

Overall, heat exchangers play a critical role in maintaining efficient. Including effective thermal management in industrial processes. This helps to ensure the smooth operation of equipment and systems. While minimizing energy consumption and operating costs.